Brick Paving on Route 66

Index to this page

- History of Brick Surfaced Roads

- Road Building technology using bricks

- The Demise of Brick Paving

- The historic Red brick section of Route 66

- More brick-paved streets along Route 66

History of Brick Surfaced Roads

The need for decent roads and highways

Dirt or gravel roads in the countryside and the cities were problematic even during the horse drawn cart age: They were uneven, the cart wheels and carriage wheels created ruts that filled with water forming puddles when it rained. Mud slowed down traffic for days until it finally dried.

Alternate surfaces had disadvantages: stone cobbles were expensive to shape and transport because they were not always available locally, especially in the Great Plains. The same can be said about gravel (with the additional work of crushing stone to make it!)

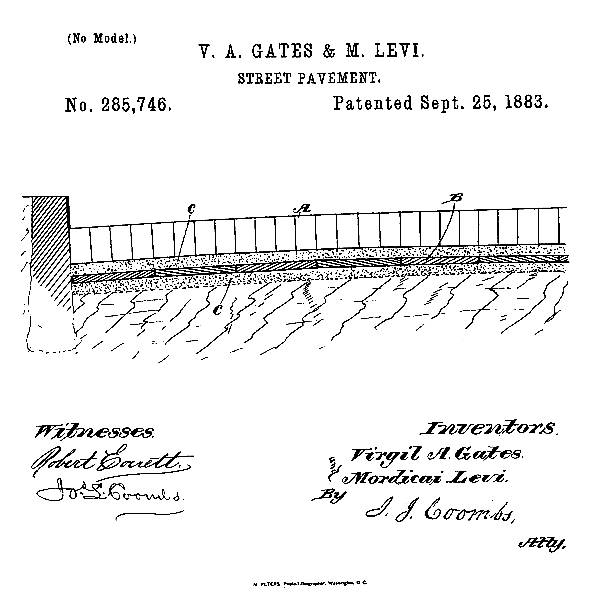

Virgil Gates and Mordecai Levi were granted a patent (No. 285,746) in 1883 for their "Steet Pavement" method of building brick pavement roads:

The object of this invention is to provide, from certain cheap materials that are common to all sections of the country, and without the use of skilled or high-priced labor, a good and durable street-pavement... and at a cost so low that small towns, as well as large and wealthy cities, can be able to avail themselves of the advantages and comforts afforded by well paved streets. US Patent 285,746 (1883)

Levi and Gates estimated a cost of 72 cents per square yard ($21 in 2022 values), so one mile of a 16-foot-wide highway would have cost in current values around $197,000.

Adoption of Brick Paving

Bricks were easy to produce locally, light, easy to transport. They provided a good road surface and they quickly became popular in the late 1800s and early 1900s for paving streets in urban settings and highways.

Early Brick-paved Streets along Future Route 66

Bloomington Illinois, 1877

The city of Bloomington Illinois claims to be the first town in Illinois to pave streets in brick and this took place back in 1877, six years before Levi & Gates patent.

There is a marker next to the old McLean County Courthouse building, on the NE corner of N Central St. (the 1926-40 Route 66) and Washington St. with the inscription: "First brick pavement in the United States Innovation to modern highways Installed 1877 by Napoleon B. Heafer. his plaque set in original paving brick and presented to the City of Bloomington May 11, 1968, by Bloomington Junior High School students."

However, this marker is incorrect; the first brick-paved street in the US was Summers St in Charleston, West Virginia, in 1873; Mordecai Levi paved one block with bricks. 1

"Get Illinois out of the mud"

The first rural brick road in Illinois was built in 1901, close to Monmouth by Brodine & Dugan at a cost of $1.2 per lineal foot with a total length of 2,000 feet. 2,3

Homer J. Tice, a farmer from Greenview IL, and representative in Illinois' lower house began introducing highway bills in 1893, but only in 1911 did he succeed with his "uniform system for automobile licenses", this served to fund the permanent improvement of hard roads (one state tax that replaced municipal taxes and that was used to improve roads). In 1913 he introduced the first State aid law of 1913, known as the Tice law. 4

Tice Act shifted the responsibility for the road system from the township to the county and required permanent roads and these were naturally built with bricks, due to the effective lobbying by Illinois brick manufacturers.

This can be seen in the road building for 1915 under the state-aid system: 20% were brick, 50% concrete, 20% were dirt and 10% were macadam, asphalt or gravel. 5

Road Building technology using bricks

Road Construction with bricks

The first brick roads were laid on the soil with a sand cushion beneath the bricks and sand-filled joints. This was inadequate because water passed in between the bricks through the sand joints, loosened the sand bed below and was absorbed by the soil, softening it.

The solution was to build a concrete foundation, lay a sand cushion on it, place the bricks close together, compress them with a roller and fill the spaces with a bituminous cement or asphalt:

Immediately after the rolling the filler should be applied. It is very important that the filler be of the highest quality of special refined asphalt so that it will adhere firmly to the brick and will not become brittle under freezing temperature or become too soft or bleed in the summer.

The filler should be poured on the pavement at a temperature of not less than three hundred (300) degrees Fahrenheit and squeeged in to the interstices, care being taken to completely fill the joints... As soon as the asphalt is poured and cooled... a coating of fine sand should be spread over the pavement to a depth of about one-half (1/2) inch and rolled into the asphalt. Construction of Brick Roads E. C. Minton (1924)

The Bricks

Bricks used for paving or "pavers" were not ordinary building bricks. They were made from shale instead of clay. They were also fired twice at high temperature, a process known as vitrification.

Glazed bricks were impervious to water and corrosion. Brick roads allowed water to percolate through, absorbing part of rainwater without expansion and contraction problems.

Vitrified bricks had a long life and were very durable and resistant to abrasion. They were subjected to rigorous tests to verify crushing and traverse strength as well as rattler resistence. 6

Durability of well made and laid bricks is outstanding; the oldest brick segment of a state highway in Illinois was built in 1915, in Ogle County (map) and it is still in use. 7, 8

The foundations

A "U-shaped" concrete foundation or base five inches thick was laid on compacted soil. It had ten inch wide curbs on each side (pictured further down). The base was then filled with a cushion one inch thick. Its purpose was to absorb the impact of traffic on the brick layer laid on top of it.

The mastic, or bituminous base, was a mix of 7 to 10% asphalt and sand and it was rolled to obtain a level surface. The bricks were laid on top.

Laying the bricks: labor and hard work

The working crews consisted of three brick laying gangs with one mastic crew, one rolling crew, one culling crew. and a filler crew. The brick-layers were the stars.

Champion Brick Layer

Indian Jim. Source

The image shows James Garfield "Indian Jim" Brown, an extraordinary brick layer. He worked on the Kansas City to Olathe brick road project, Higway 50, in the 1920s. He became famous as the "Champion brick layer of the United States" having set 218 tons of bricks in less than 7 hours.

Indian Jim worked for the McCarthy Improvement Co., of Davenport Indiana. The company had been in charge of a resurfacing job on Route 5 between Chatham and Abuburn in 1933. Jim could lay 1,600 sq. yards per day all by himself.

The image below shows a group of road building workers laying bricks in Illinois in the early 1920s. Note the concrete curbs on each side, the bituminous base and the men laying the bricks:

Road building crew laying bricks ca.1920s in Illinois, on a cushion bituminous base.

Another view of the crew:

The Historic Brick Road (Route 66), notice the concrete curb. Auburn, Illinois

The bricks could expand and contract without cracking due to the space around them. In the case of old State Highway 4 you can stil see on both sides of the road a 10 inch-wide concrete curb (see image above).

The historic Red brick section of Route 66

Listed in the National Register of Historic Places

See this map with directions along the brick segment.

Illinois state highway 4 ran south from Springfield to Hamel via Chatham and Auburn. It had originally been paved with Portland concrete in 1921. The roadway became US 66 in 1926. Four years later Route 66 was realigned further east via Litchfield and Mt. Olive, removing it from the old IL-4 alignment.

One of the reasons for its realignment was to remove the sharp ninety-degree turns of the old alignment and give it a straighter and safer course.

Red brick Route 66, Auburn Illinois

In 1932, during the Great Depression, state hwy 4 was improved. The roadway was widened and many of the sharp 90° curves were eliminated. The Auburn segment was improved and its western part was resurfaced with bricks: the segment that ran along Snell and Curran Roads. The sharp curve at their junction was also softened to a wide arch. 9, 10

The image below shows a detail from the 1924 USGS map of Snell Road north of Auburn and the solid red line marks what in those days was State Highway 4; notice the sharp curves to the right and left (east and west).

The northern part was straightened (red dashed line) bypassing the eastern 90°curve at Hambuch Rd. The old segment here was not upkept and still lies in the fields, cracked concrete, overgrown with weeds (street view of the old concrete section).

The new straight alignment then turned right onto Snell Rd. which was paved with bricks, a soft curve was added at Curran Rd., and this road was also surfaced with bricks.

The current alignment of IL-4 south of Snell Rd. marked with a dashed blue line with a diagonal course from right Snell to Curran Rds. was not paved until the 1960s; it does not appear in any aerial photograph of this spot (see this 1956 aerial picture as an example) until 1971.

In the 1956 aerial photo you can see the original 1920s sharp curve at Snell Rd. and Curran Rd. (upper left side of image) and the red-brick wider curve built in 1932.

USGS map from 1924, Auburn, Il

The image above shows a curent view of the same spot. The ninety-degree curve on the right (east) is the original 1920s concrete-paved segment between modern IL-4 and Hambuch Rd (red arrow) replaced in 1932. The red arrow to the left is the red brick road's wide curve.

The Demise of Brick Paving

Bates Testing Center

Engineers of the Illinois Divison of Highays or IDH investigated the performance of different types of road surfaces between 1920 and 1923. They were trying to identify the best paving for the state's highways.

So they built an experimental road segment in Bates Illinois: a two-miles-lon (3.2 km) stretch of road paved with different kinds of pavements (seeking better durability, performance under real highway load conditions.

This stretch of road was 18 feet wide (5.5 m) and had 24 concrete segments, 17 asphalt ones, and 22 brick sections. Their length was on average 180 feet (60 m). They used sensor to detect the strain and forces on the roadway as U.S. Army trucks carrying loads of 10 tons drove along the road thousands of times. They also measured the warping caused by temperature variations (brick surfaces deformed the least), the impact of loads due to steps in the roadway, and how the subgrade soil affected the road above. 11

Concrete and asphalt performed better than bricks

The road cracked and failed under the heavy trucks and the engineers recorded the performance. They found that vitrified bricks with a bituminous joint filler laid on a concrete base didn't behave as expected. It was supposed to bond as a "monolithic brick" and concrete block (hence its technical name "mono" = "one" and "lithic" = "stone"), but instead it behaved as two separate slabs that slid and cracked along the edges. It "(did) not add materially to the strength of the base, but by lessening exessive impact... g(a)ve consideraly increased resistance to progressive destruction."

But the increasing availability of synthetic asphalt began to displace bricks. Furthermore, bricks were laid by hand, a labor-intensive and time-consuming task. Asphalt laying was quicker and mechanized.

Nevertheless, as Auburn shows, even as late as 1932 roads were still being surfaced with bricks -maybe to employ idle men who had lost their jobs during the Depression (?)

The Brick Paved Route 66 in Illinois

More brick-paved streets along Route 66

You can visit many urban streets paved with bricks along Route 66 from Illinois to Texas. We describe some of them in this section.

Illinois

Lincoln

Next to Route 66's alignment in Lincoln is a brick-paved street: On the corner of 5th St (US66) and Logan, look right, South Logan St. is paved with red bricks (street view).

Carlinville

On the 1926-30 US 66 alignment in Carlinville the streets around the town's main square have brick paving (pictured below):

Loomis House (St. George Hotel) and brick paved street:

Edwardsville

In Edwardsville at Route 66 (Vandalia) and S. Filmore Street is another example (St. view).

Mitchell

Route 66 through Mitchell as you can see in the picture below (taken in 1933) shows the Luna Cafe (red arrow) and the brick-surfaced highway. Notice the 10-inch-wide concrete curbs on both sides of the highway.

This is the same spot nowadays; the bricks have been replaced with asphalt paving.

Oklahoma

Davenport

Listed in the National Register of Historic Places

Davenport has a historic brick paved street: Broadway.

Broadway Street, Davenport

When Route 66 was commissioned in 1926 traffic through the town increased and the local government paved the Main Street with vitrified bricks. These were made locally by the Davenport Brick & Tile Company.

It originally ran from the Frisco tracks to te north side of the town on Sixth St. along Broadway. The width of the brick paving varies between 30 and 72 feet. The bricks are of a uniform size measuring 2.4 by 4 by 8 inches, and they are set in sand. There is a concrete apron five ft. wide at each curb. At the intersections the bricks were laid with a decorative feature, forming an X centered in the middle of the intersection.

The Main Street is known as "Snuff Street", and the reason is that at each street crossing there were dips which made the cars "take a dip" every block.

Bristow

Bristow has more brick-paved streets than any other town in Oklahoma.

The corner of Route 66 (Main) and W 6th (notice the brick paving on 6th - lower left).

Sapulpa

The Historic bridge in Sapulpa, known as Bridge #18 at Rock Creek has a red-brick deck.

Listed in the National Register of Historic Places

This steel truss bridge carries the 1926 Route 66 alignment across Rock Creek. It was built in 1924 and remained part of Route 66 until the highway was realigned in 1952.

Weatherford

There are several brick street sin Weatherford (Custer is one of them). Several blocks of Main Street (Route 66) were paved in brick until the mid-1950s when it was widened to a four-lane thoroughfare and the bricks were removed.

Texas

Shamrock

While visiting Shamrock, as you drive to visit its classic Magnolia gas station, don't miss the red-brick paving along Second Street. Pictured below.

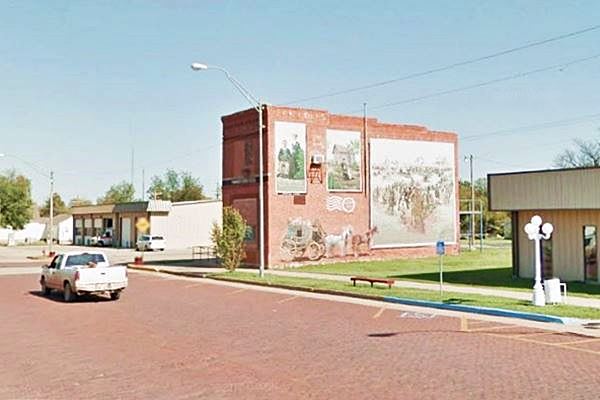

McLean

Main street in McLean, pictured above is paved with red bricks and crosses US 66 in the historic commercial downtown district.

Amarillo

You will notice many brick-paved streets in Amarillo: Local citizens voted in 1910 for streets to be paved with bricks. The downtown area of the city still has 16.2 mi (26.1 km) of red brick streets, which it diligently restores.

Some sponsored content

>> Book your Hotel in Oklahoma City

Credits

Banner image: Hackberry General Store, Hackberry, Arizona by Perla Eichenblat